Will Smith – Director of Software, Adcole LLC

什么是聊天及其来源

振纹是一种重复出现的小波峰或 "起伏 "图案,每隔一定时间就会出现一次,并可能出现在机加工件的成品表面上。 喋喋不休 不是形状误差(圆度和叶形),颤振也不是 表面处理 (粗糙度)之间存在。在关键部件中,如发动机或电机中的旋转轴,颤振会在最终装配中产生问题,导致部件过早失效并损坏其他部件。本文将探讨轴部件产生颤振的原因、评估方法和测量结果,以提高高要求组件的轴质量。

异响是发动机噪音、振动和声振粗糙度(NVH)的一个主要来源,但只要采用适当的优质工艺和设备,异响就会消失。任何加工操作,如铣、车、镗、磨等,都可能产生颤振。更具体地说,颤振通常是由刀具不平衡、刀具或夹具刚度不足、非各向同性零件刚度(曲轴的一个特殊问题)、零件中心偏圆、设备故障或磨损以及其他不平衡或振动源引起的。

喋喋不休检查为何重要

Modern motors and internal combustion engines (ICE) demand tighter tolerances and higher performance, making efficiency and longevity crucial. Rotating shafts with chatter patterns can cause excessive noise and vibration issues within the final assembly of an engine or motor, potentially leading to NVH concerns that could require recalls, which can lead to customer dissatisfaction, reputational damage, and loss of sales. This is particularly true in high RPM requirements such as EV rotor shafts, which can reach 20,000 RPM or more.

Chatter is a feature that has been measured and analyzed by manufacturers for decades, but is also overlooked when designing a new part. Whether for engines or motors, this parameter can be critical to monitor. While production machines are often prioritized in budgets, quality control equipment is equally important. Poor quality can be costly, so engineers and production managers must develop robust quality control systems and ensure they have the right equipment to measure necessary features.

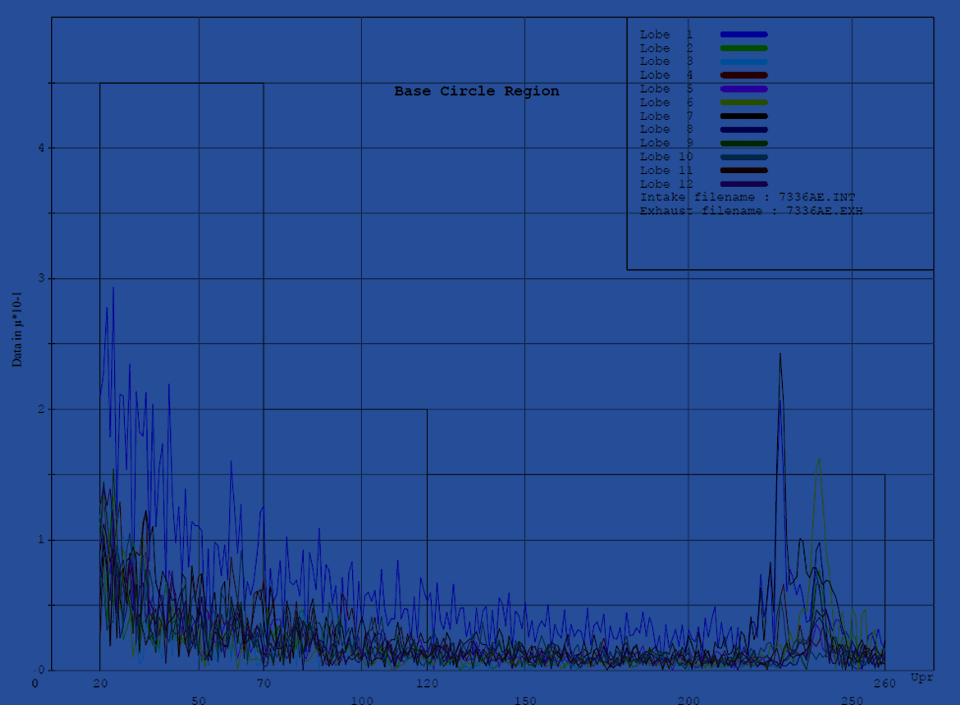

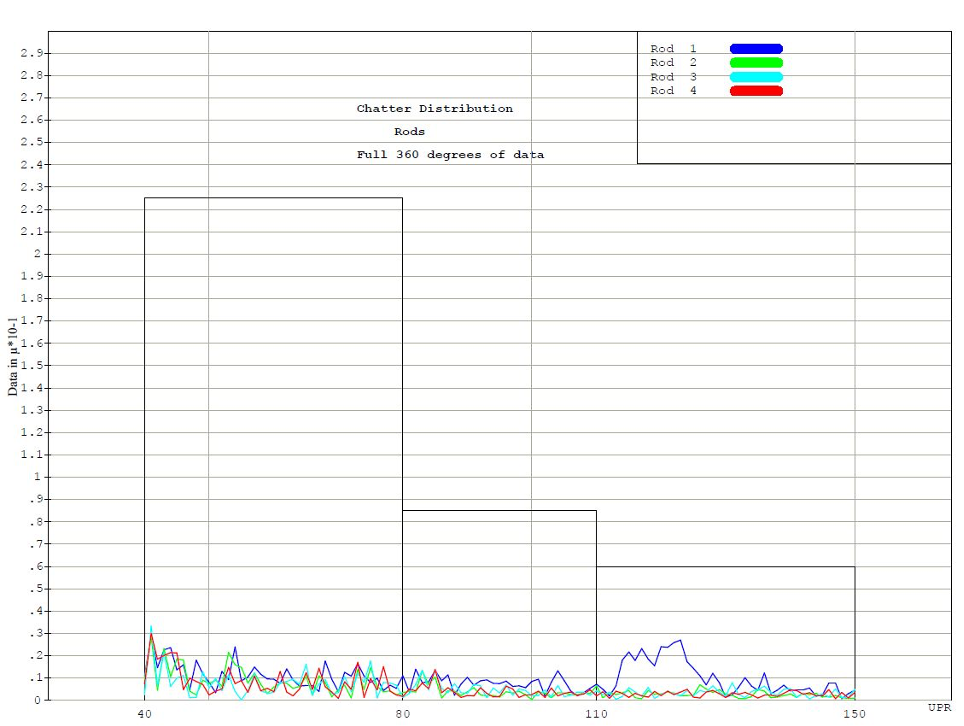

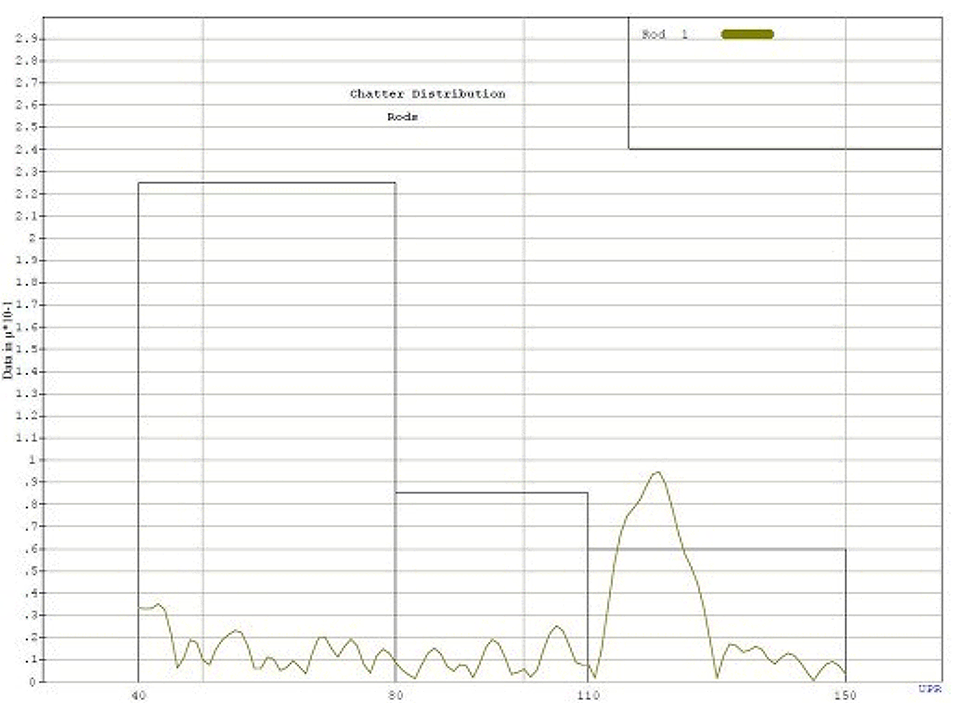

颤振通常发生在与砂轮或切削刀具旋转速度和工件旋转速度比例相关的特定频率上。 由此产生的工艺 "固有频率 "会显示出一致的特征,在频域图中通常会出现较高的谐波。 调整工艺参数可控制 "固有频率 "的振幅和/或改变发生频率,以满足产品要求。 该频率下振幅值的增加和/或其他频率下额外的振幅尖峰/峰值通常表明存在与工艺相关的问题或外部影响。 外部影响可能包括附近的电机、泵、其他设备(如冲压或压制机器)或叉车交通。 颤振输出有助于引导技术人员和工程师找到问题的根源,从而进行纠正并恢复产品质量。

如何检查喋喋不休

设备

Quality control machines are optimized to measure a specific set of parameters; for example, a precision tactile machine can often measure chatter, while an optical machine cannot (or not as effectively). Chatter is not something that would be detected by evaluating standard GD&T features like roundness or refinements of roundness data such as sector roundness or lobing. The amplitude can be quite small at sub-micron levels, the chatter may be limited to a single area, and the frequency of the chatter may vary significantly. However, regardless of the amplitude, region, or frequency variations, chatter can still have a discernible impact on the quality, final assembly, and performance of ICE or electric motors.

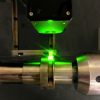

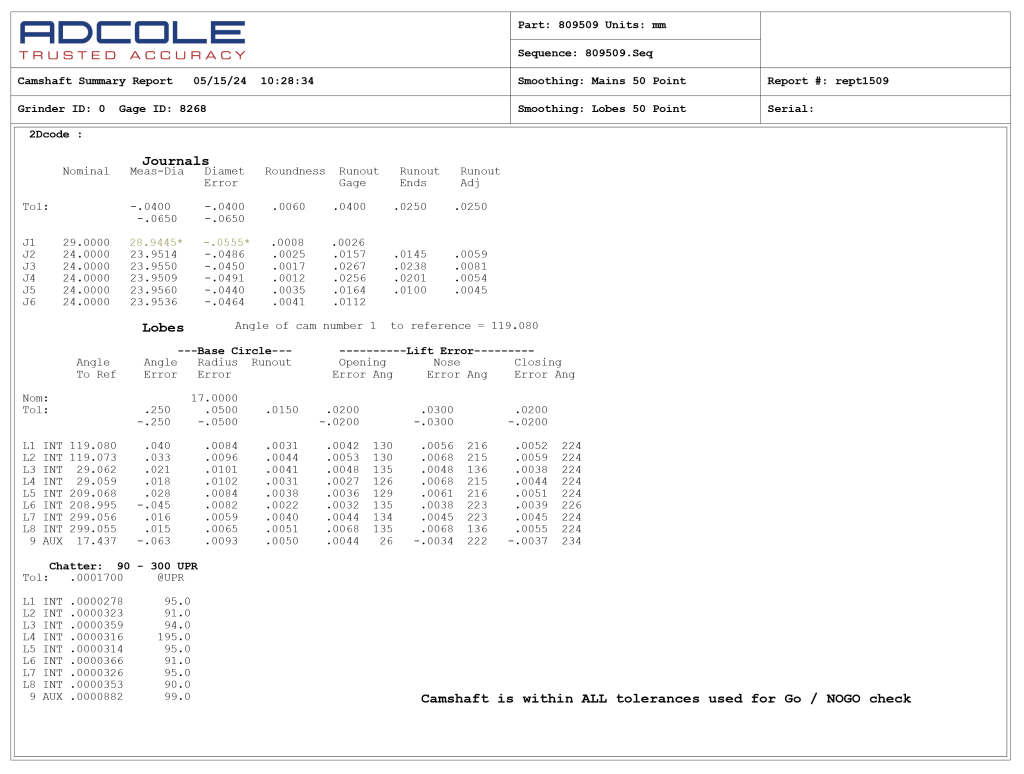

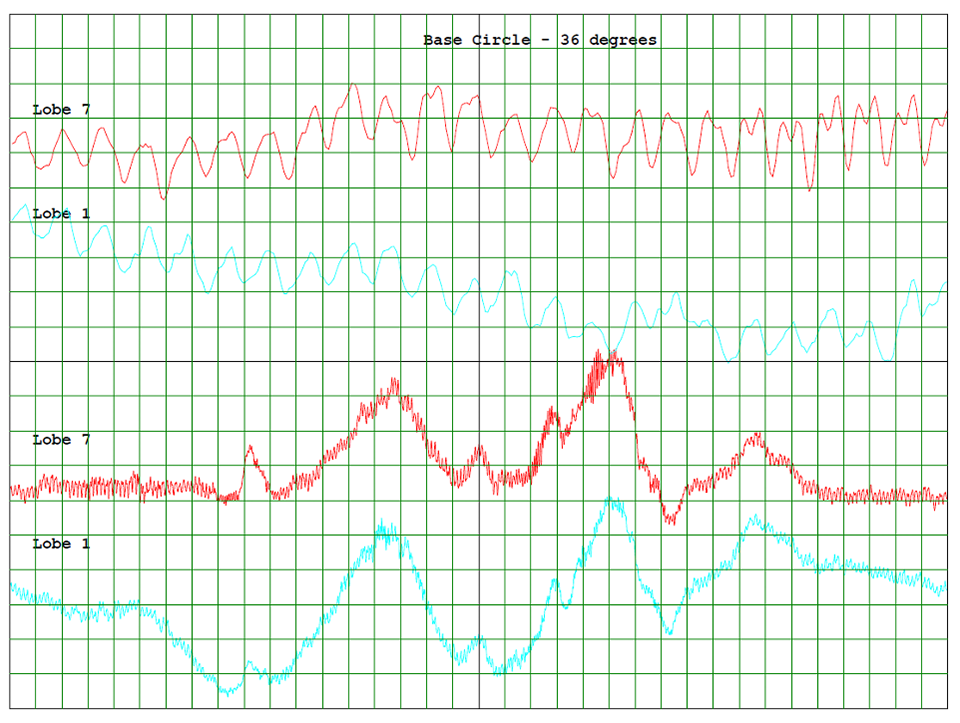

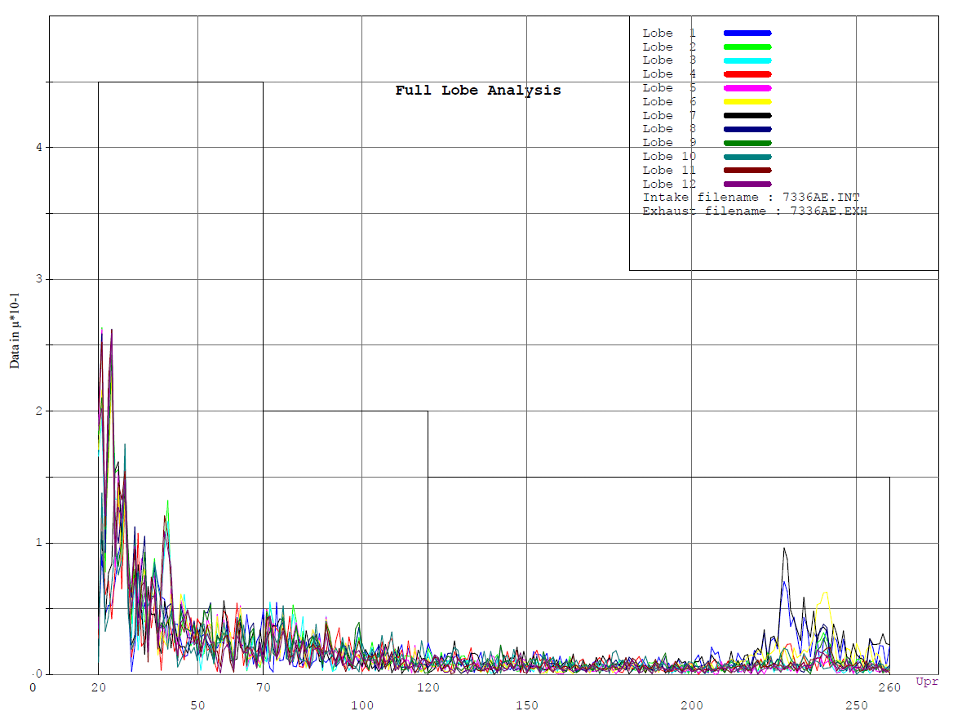

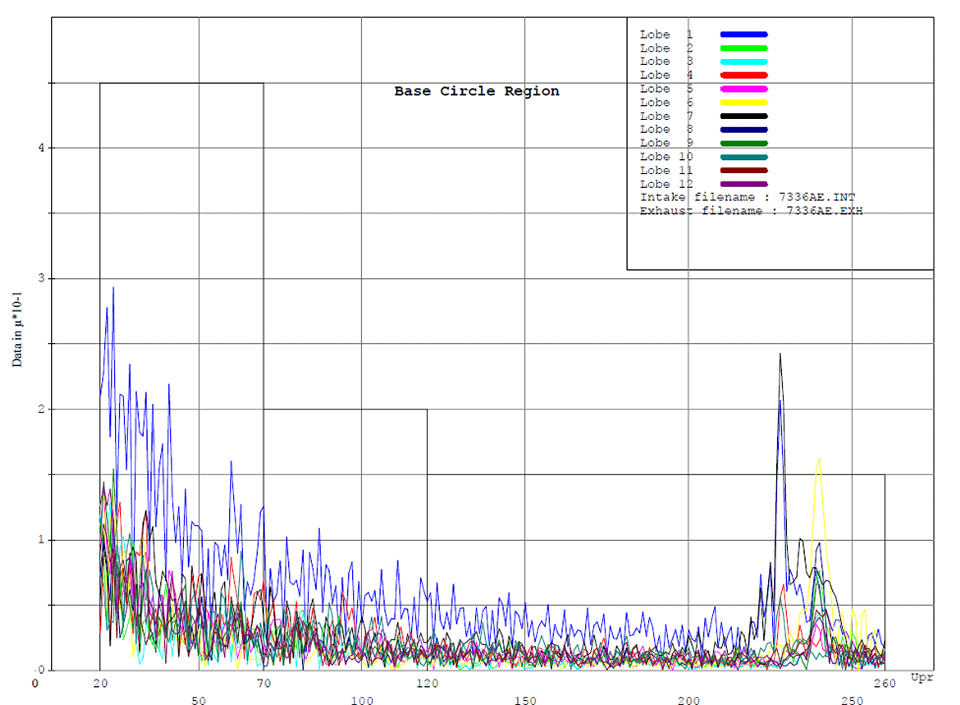

一个 tool for measuring chatter on shafts after a grinding process would be an Adcole tactile shaft metrology gage. These gages, along with proper software that can measure a wide range of GD&T parameters, provide valuable data and analysis to maintain the demanding quality required for rotating shafts. In the camshaft world, analysis of a lobe base circle region where the grinder velocity would be uniform over a constant radius provides a cleaner signal for detecting a chatter issue. The lift region of the lobe where radii rapidly changes could be analyzed separately, providing additional information over the surface that would have been ground with an adjustable velocity.

评估方法

"由于许多与振动有关的问题都发生在特定频率上,因此可以根据特定频率上的振幅变化来缩小或确定振动的原因和位置。” (Collins D., 2022) This is why calculating amplitude over a frequency domain is better than simply counting lobes or peaks within the profile error.

所有测量数据都直接进入数据采集软件,该软件以振幅与时间的关系(即时间波形)或振幅与频率的关系(即快速傅立叶变换 (FFT))记录信号,或两者兼而有之。所有这些数据都会通过计算机程序算法进行分析,然后再由工程师或训练有素的振动分析师进行分析,以确定机器的健康状况,并识别可能即将出现的问题,如松动、不平衡、错位、润滑问题等。振动分析可以检测出车轮不平衡或车轮修整等问题。

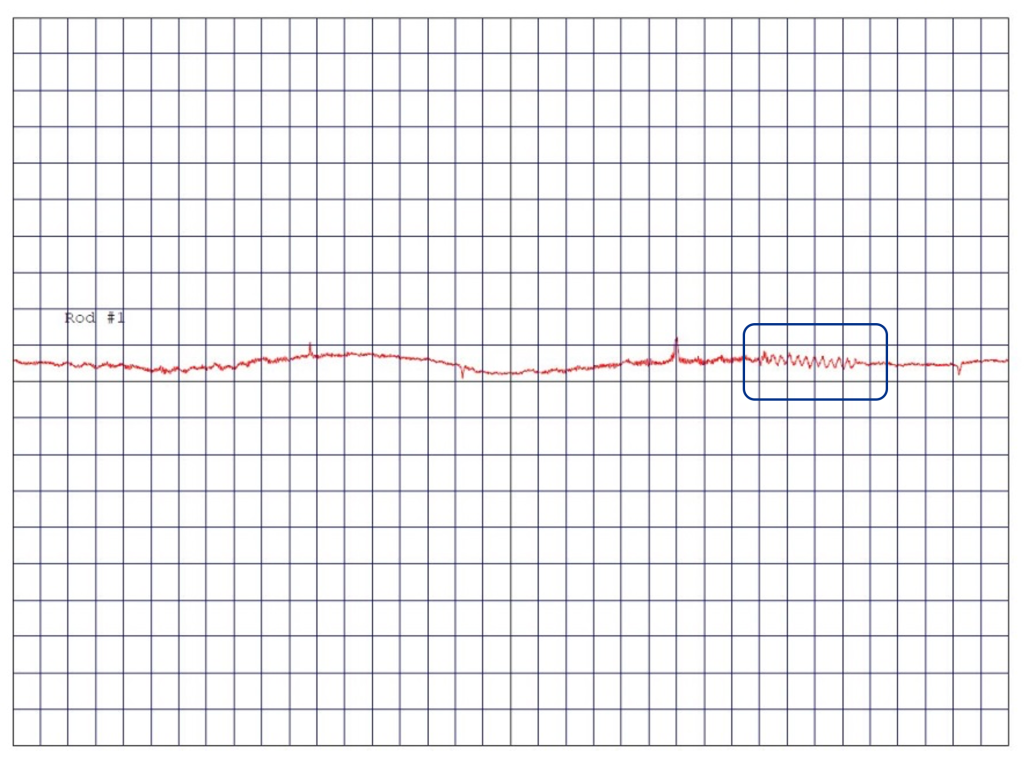

Chatter can also mask itself on a shaft journal by showing up only over a small angular range. This makes it more difficult to measure and detect. Another method is the quadrant analysis option that can be used for journals on any rotating shaft. This allows for the entire 360 degrees of roundness data to be analyzed for chatter, and it breaks the roundness error into four 90-degree regions for chatter analysis. This analysis option provides a tool that can pick up a “chatter burst” on the surface of a journal where during the production process, a region of usually less than 90 degrees exhibits a pattern of undulations. The amplitude of these undulations is frequently too small to affect the roundness or even lobing measurement parameters, but can still cause issues with NVH in the final assembly of the engine. By analyzing the roundness error over 90 degrees, it is possible to measure a higher amplitude of chatter that may exceed the defined tolerance.

在有限的角度范围内寻找颤振的一种方法是使用 "滑动窗口 "法。这种方法可以设置角度窗口的度数和滑动增量。该滑动窗口将遍历 360 度的圆度或轮廓误差数据,并确定最大振幅和发生振幅的角度区域。同样重要的是,必要的测试允许在指定的角度区域内分析颤振公差和颤振范围。这可以基于对已知 "噪声 "轴进行一系列测试,并与已知 "安静 "轴的同一系列测试进行比较。

杂音测量输出

振纹在零件表面出现的方式各不相同。有时,它会出现在一个较大的角度窗口内,并有一个干净的频率。这有可能在被测特定元素的圆度或轮廓误差图中看到。不过,圆度或轮廓误差图中也可能会掩盖颤振,因为这些误差图通常会对误差数据进行过滤,从而掩盖颤振。

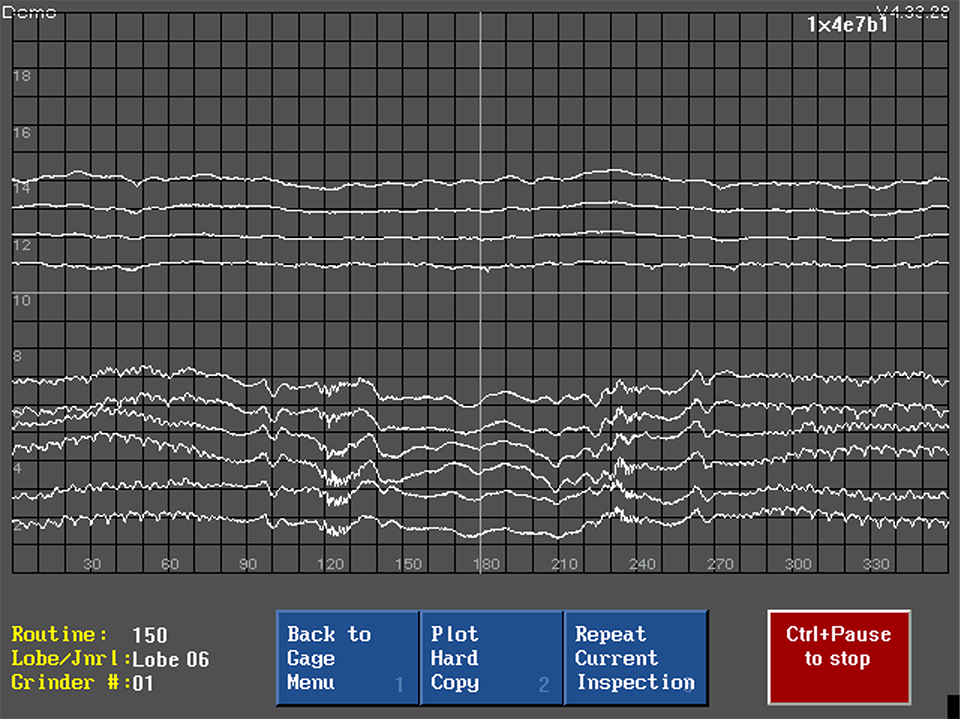

在 Figure 2a在 "凸轮轴叶轮廓图 "中,有一个轴颈圆度和凸轮轴叶轮廓误差图,六个凸轮轴叶位于图的底部。这些凸轮叶轮廓图显示了 0-90 度和 270-360 度之间的基圆区域。升程区域误差为 90-270 度。在这个示例中,您可以看到基圆区域有明显的起伏。由于基圆的半径是恒定的,因此它通常以恒定的速度磨削,而升力区则不然。

一些公司使用叶片计数过程来确定制造过程中的问题。这对于确定圆度或轮廓误差中表现出不合格的角度区域很有价值,但它也有不足之处,因为它依赖于内部定义如何定义波纹或峰值,以便对其进行计数。这种方法通常不会在峰值之间寻找等间距,因此无法确定出现的具体频率。

结论

测量颤振对于始终如一地生产高质量的轴至关重要,这样的轴可以在不产生噪音和振动的情况下长期运行,而噪音和振动会加速零件的磨损或故障。精密旋转部件在高速旋转时如果出现可测量到的颤振,可能会导致发动机或系统完全失效。如果拥有先进的分析工具,可以查看特定区域的表面颤振,就能在产品出厂前发现制造中的问题。轴制造商应计划投资购买适当的质量工具或量具,用于在线或审计室设置,以分析制造过程中超出规定公差的潜在错误,并采取措施加以纠正。

Collins, D. (2022, October 17). How are fast Fourier transforms used in vibration analysis. Motion Control Tips. https://www.motioncontroltips.com/how-are-fast-fourier-transforms-used-in-vibration-analysis/