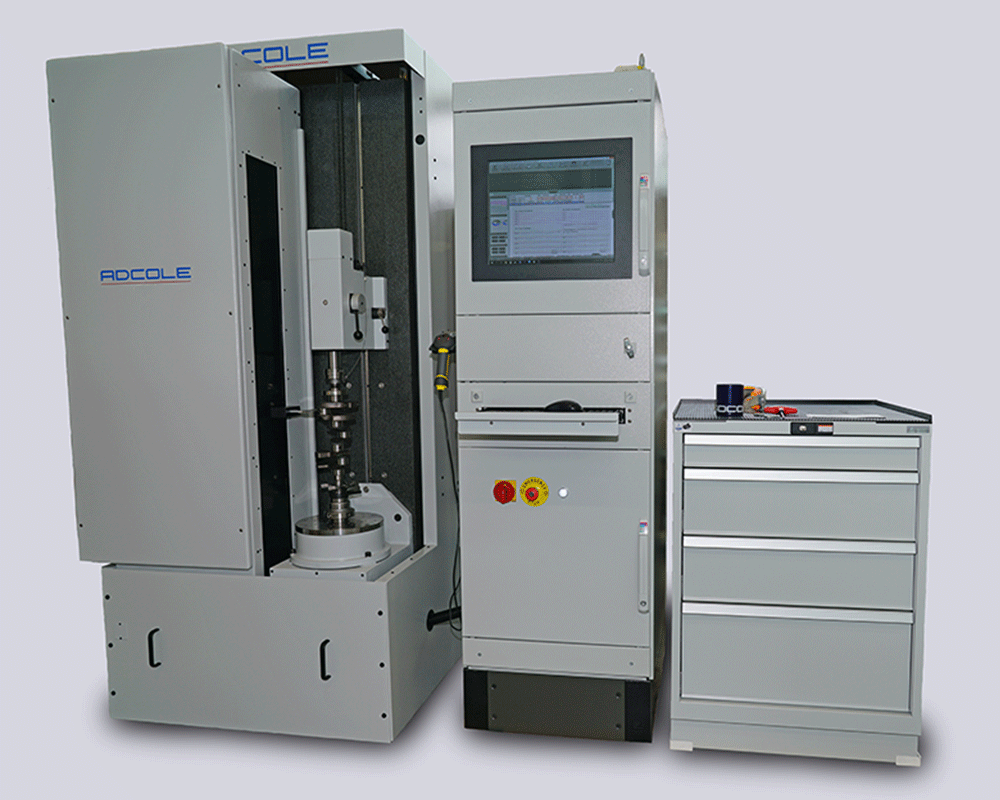

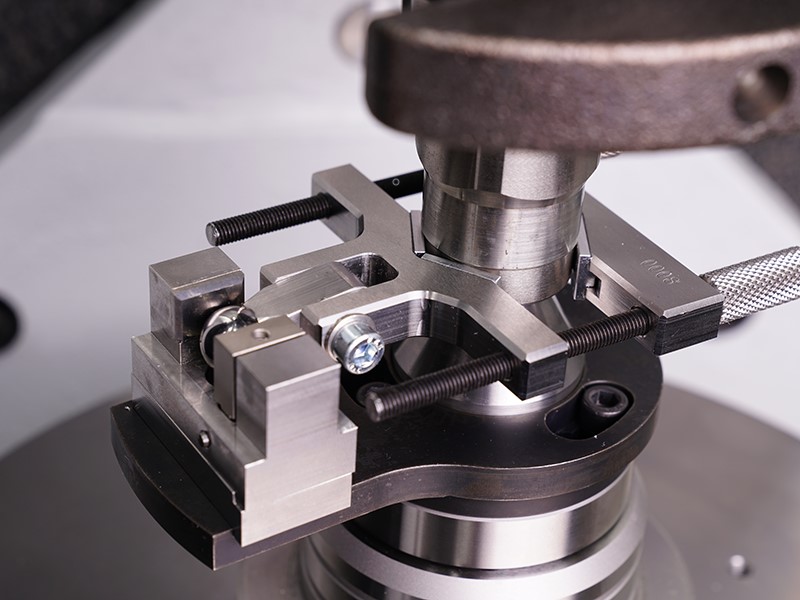

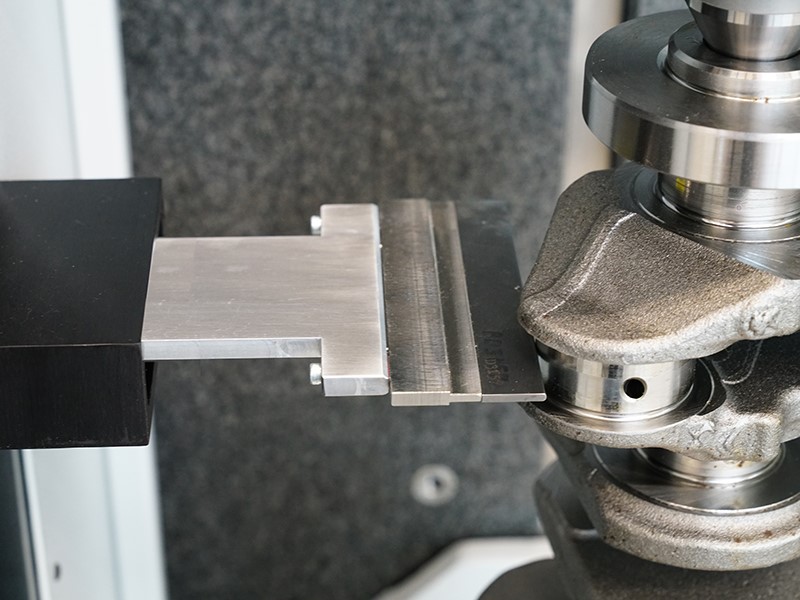

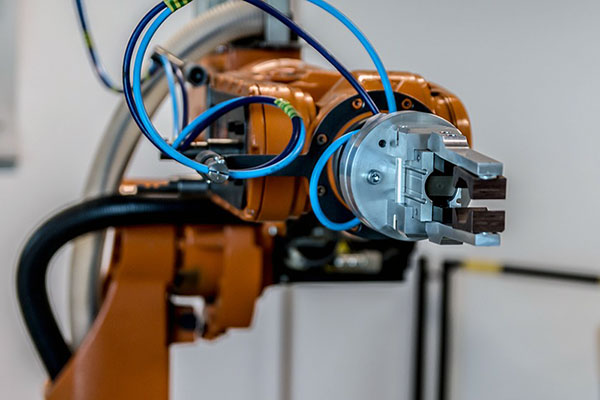

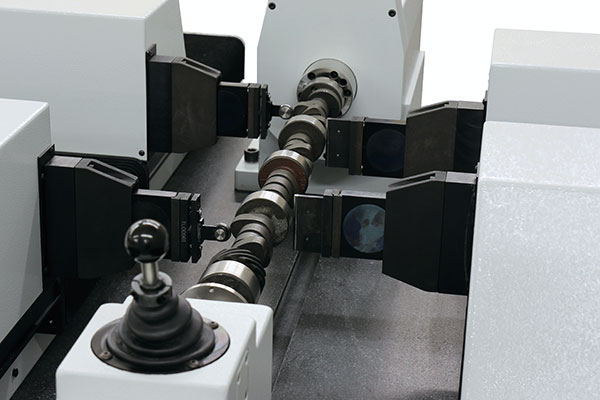

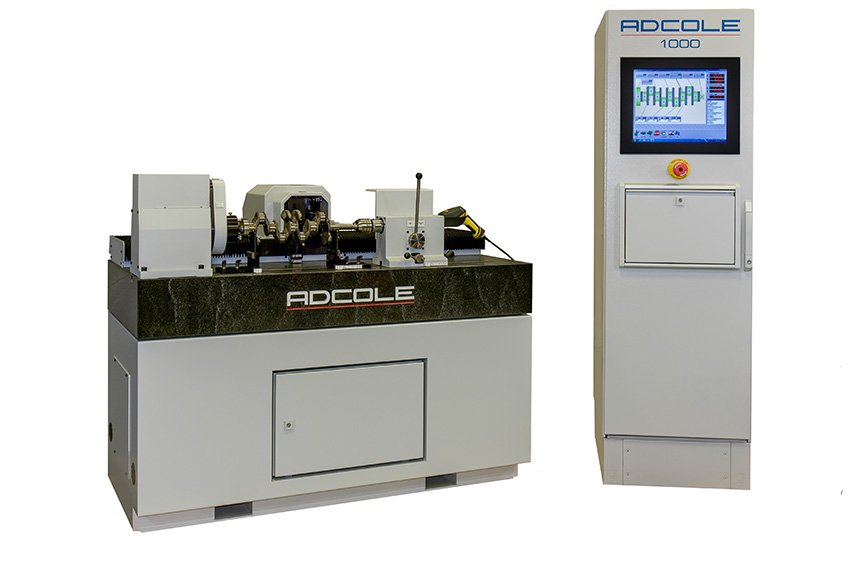

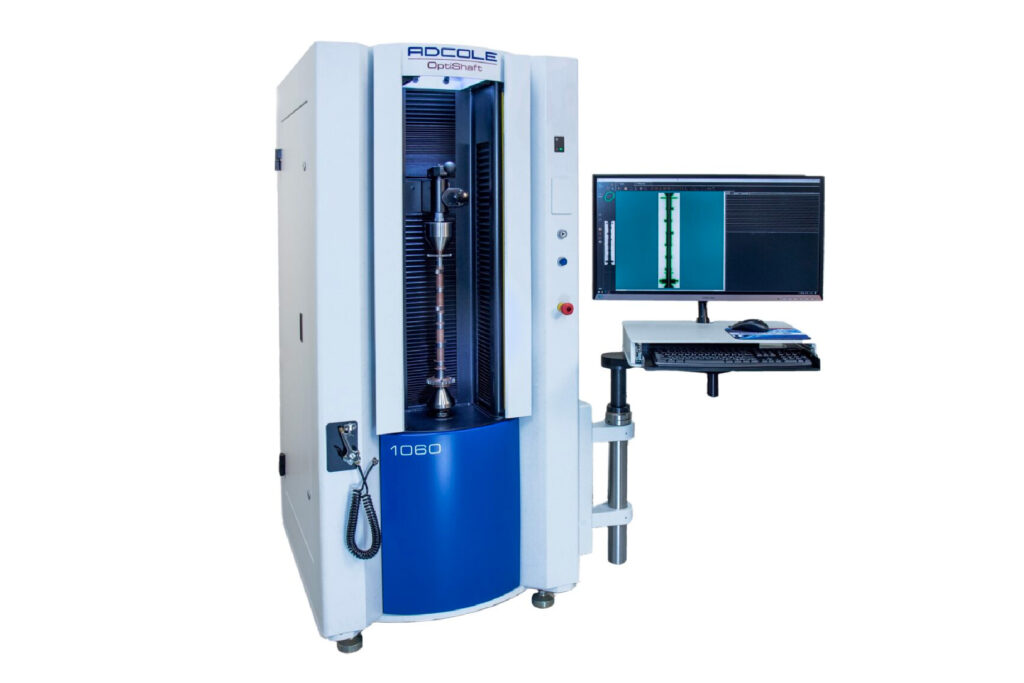

The Adcole Model 1100-S gage is engineered to provide advanced manufacturers with an accurate, reliable and value-driven gage for production floor or metrology laboratory use. Engineered to the same exacting standards built into every one of Adcole’s “Trusted Accuracy” gage models, the 1100-S helps organizations improve part quality, reduce scrap, and increase manufacturing efficiency.

The Model 1100-S is ideal for measuring complex features on:

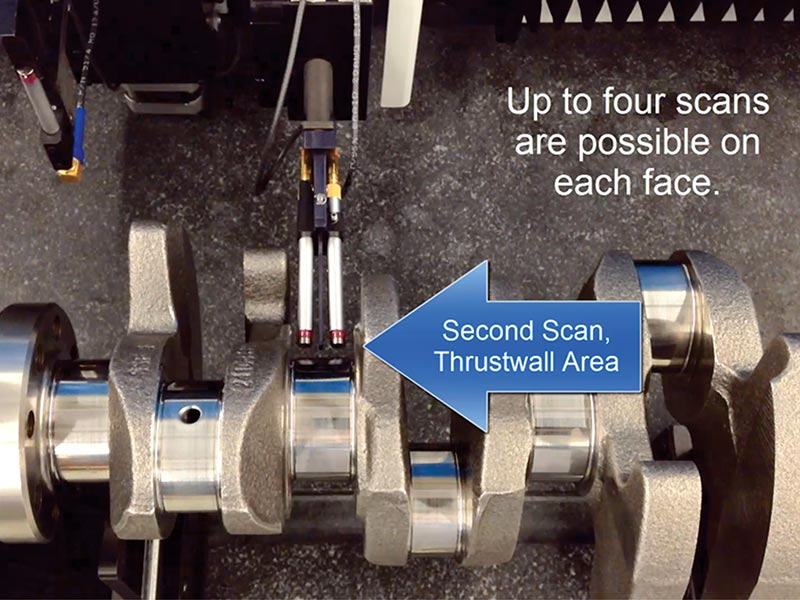

- Crankshafts

- Camshafts

- Electric vehicle rotor shafts

- Eccentric shafts

- Transmission output shafts

- Other cylindrical parts