1300 Series Shaft Measuring Machines

Multi-Head & High Throughput

Overview

The Adcole 1300 Series represents a high-speed solution for high-precision shaft measurement in demanding manufacturing environments. Designed typically for in-line 100% inspection production environments to meet the rigorous quality standards of industries such as transportation, aerospace, and electric vehicle (EV) production, these gages deliver exceptional speed, flexibility, and accuracy. Ideal for parts that require tight geometric tolerances, 1300 series gages ensure that every component meets exacting specifications.

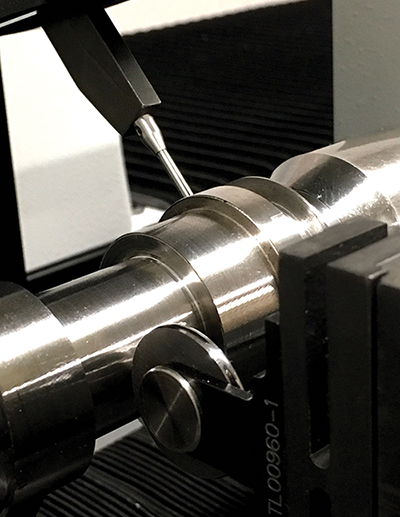

What distinguishes the Adcole 1300 Series gages from other shaft measuring systems is their horizontal design, which enables seamless in-line robotic loading for efficient integration into automated production lines. Additionally, the use of multiple, customizable followers—ranging from 2 to 28 depending on the model and shaft complexity—significantly enhances measurement throughput without compromising accuracy. Each follower probe captures 3,600 data points per revolution (0.1º) with an angular resolution of 0.00001º and a radial accuracy of 0.50 µm. This combination of speed, precision, and configurability makes the 1300 Series ideal for high-volume, high-precision manufacturing environments.

1302: Compact Shaft Gage

The Adcole Model 1302 is purpose-built for measuring shafts under 12 inches in length, making it ideal for camshafts, sliding camshaft elements, and other complex cylindrical components. This compact, horizontal coordinate measuring machine (CCMM) features a dual-head configuration, enabling simultaneous measurements that significantly reduce cycle times.

Engineered for high-precision applications, the Model 1302 delivers sub-micron accuracy and repeatability, ensuring reliable performance in both production and quality control environments.

Specifications

| 1302 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolution | 0.016 µm | |||||||

| Axial Accuracy | ±2 µm over 100 mm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.15 µm | |||||||

| General Specifications | ||||||||

| Rotation Speed Max. | 40 RPM | |||||||

| Swing Diameterii | 178mm (7") | |||||||

| Part Weight Max. | 36 kg (80 lb) | |||||||

| Part Length Max. | 305mm (12") | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 1,214mm (47.81") | |||||||

| Gage Width | 1,156mm (45.50") | |||||||

| Gage Depth | 1,111mm (43.75") | |||||||

| Gage Weightiii | 2,270 kg (5,000 lb) | |||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii 105mm (4.13”) with Camtracker option

iii Weight does not include add-ons or cabinet

1304/1306: Multi-Head & High-Throughput Shaft Gage

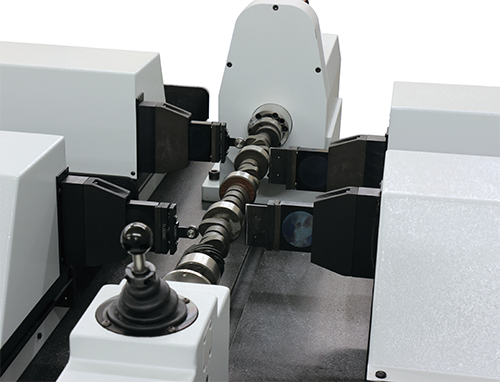

For shafts that exceed the capacity of the Model 1302, the Adcole Models 1304 and 1306 are the next evolution in the horizontal 1300 series—designed to meet both in-line and audit shaft measurement needs.

These gages feature two or four independent measuring heads that can traverse beyond the headstock and tailstock, significantly reducing fixture costs and enabling efficient part loading and unloading. Boasting high throughput and fast cycle times, the 1304 and 1306 models also offer an optional programmable power tailstock, ideal for robotic or gantry loading in high-volume production environments.

Key capabilities include:

- Measurement of shafts up to 2286 mm (90 inches) in length

- Support for parts up to 180 kg (400 lbs)

- Durable flat and disc carbide follower tips

- Axial accuracy of ±2 µm over 100 mm

Whether you’re scaling up for longer, heavier shafts or optimizing for automation, the 1304 and 1306 deliver precision, flexibility, and performance.

Specifications

| 1304 (24") | 1304 (42") | 1306 (24") | 1306 (90") | 1306 (96") | ||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolutioni | 0.016 µm | |||||||

| Axial Accuracy | ±2.0 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Follower Heads | 4 | 2 | ||||||

| Swing Diameter | 190mm (7.5") | 178mm (7") | 350mm (13.78") | |||||

| Part Weight Max. | 36 kg (80 lb) | 45 kg (100 lb) | 180 kg (400 lb) | |||||

| Part Length Max.ii | 965mm (38") | 1,520mm (59.8") | 609mm (24") | 2,286mm (90") | 2,438mm (96") | |||

| Base Gage Dimensions | ||||||||

| Gage Height | 1,239mm (48.8") | 1,016mm (40") | 1,283mm (50.5") | |||||

| Gage Width | 1,708mm (67.25") | 887mm (34.9") | 1,740mm (68.5") | 3,658mm (144") | ||||

| Gage Depth | 1,111mm (43.75") | 826mm (32.5") | 1,016mm (40") | |||||

| Gage Weightiii | 1,708 kg (3,760 lb) | 2,409 kg (5,300 lb) | 1,814 kg (4,000 lb) | 5,400 kg (12,000 lb) | ||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

1310: Flexible In-Line Automated Shaft Gage

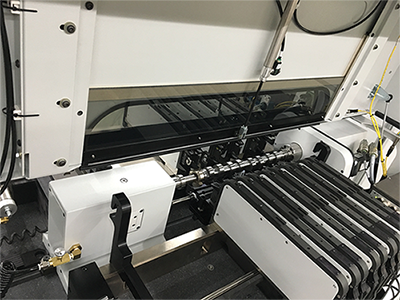

Engineered for in-line production environments, the Adcole Model 1310 delivers industry-leading shaft measurement speed with support from up to 28 followers. When integrated into an automated process cell, this advanced gage can inspect up to 200 parts per hour—while maintaining the sub-micron accuracy that defines every Adcole Shaft Measuring Gage.

With the ability to fully measure a camshaft in under 20 seconds (excluding loading and unloading), the Model 1310 accommodates parts up to 609 mm (24 inches) in length and a 102 mm (4 inches) swing diameter.

Key features include:

- Modular gage design for simplified maintenance and fast part changeovers

- Multi-part programming with automatic part detection and sequence selection

- Minimized downtime by eliminating the need for frequent reprogramming or retooling

Whether you’re optimizing for speed, precision, or flexibility, the Adcole Model 1310 sets the standard for automated shaft measurement.

Specifications

| 1310 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolution | 0.016 µm | |||||||

| Axial Accuracy | ±2 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Follower Heads | Up to 28 | |||||||

| Follower Stroke | 51mm (2") | |||||||

| Swing Diameter | 102mm (4") | |||||||

| Part Weight Max. | 25 kg (55 lb) | |||||||

| Part Length Max.ii | 609mm (24") | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,004mm (80") | |||||||

| Gage Width | 887mm (34.9") | |||||||

| Gage Depth | 1,195mm (47") | |||||||

| Gage Weightiii | 2,160 kg (4,760 lb) | |||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

1310-S: In-Line Automated Shaft Gage

The Adcole Model 1310-S is a horizontal CCMM designed for single part-length measurement applications. Built with the same robust capacity as the standard Model 1310, the 1310-S offers a streamlined feature set, making it a value-oriented solution for manufacturers focused on measuring a single part type.

Customers can enhance the system with an optional linear scan capability, enabling the measurement of multiple cuts on complex parts. The gage features a fixed headstock and a pneumatic tailstock with 30 mm of travel (with an optional upgrade to 60 mm), supporting efficient and repeatable part loading.

Ideal for operations seeking high-precision measurement without the need for multi-part flexibility, the 1310-S delivers reliable performance at a lower cost of ownership.

Specifications

| 1310-S | ||||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolutioni | 0.016 µm | |||||||

| Axial Accuracy by LVDTi | ±2 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Follower Heads | Up to 24 | |||||||

| Follower Stroke | 51mm (2") | |||||||

| Swing Diameter | 102mm (4") | |||||||

| Part Weight Max. | 25 kg (55 lb) | |||||||

| Part Length Max.ii | 609mm (24") | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,229mm (90.5") | |||||||

| Gage Width | 887mm (34.9") | |||||||

| Gage Depth | 1,195mm (47") | |||||||

| Gage Weightiii | 2,380 kg (5,250 lb) | |||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

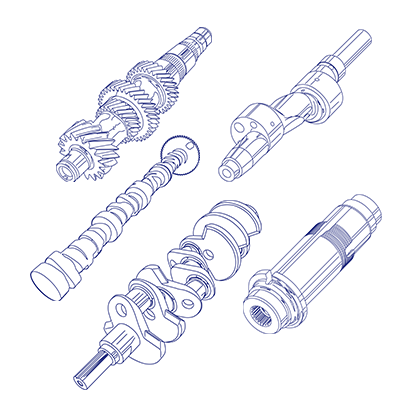

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.