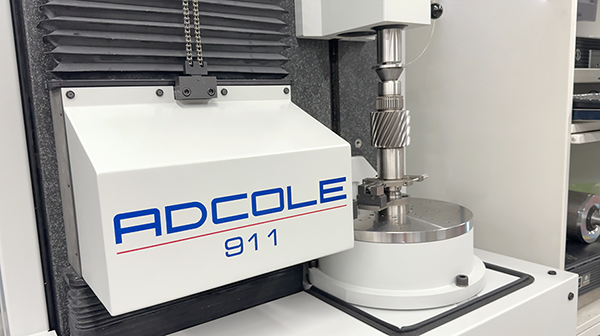

911 Shaft Measuring Machine

Flexible Metrology Gage

Overview

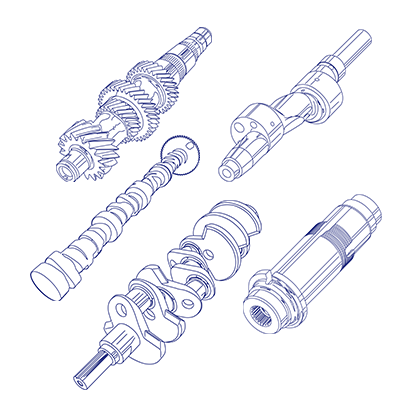

The Adcole Model 911 is the gold standard in precision shaft metrology, trusted by manufacturers worldwide for over four decades. Engineered for versatility, this semi-automated gage delivers submicron accuracy across a wide range of cylindrical components—including EV rotor drive and output shafts, balance and eccentric shafts, camshafts, transmission shafts, and more.

Its robust design and advanced measurement capabilities make it ideal for both shop floor and metrology lab environments. With high-resolution data acquisition, intuitive software, and flexible part handling, the Model 911 ensures consistent, reliable results in automotive, aerospace, and industrial applications.

911 Benefits & Capabilities

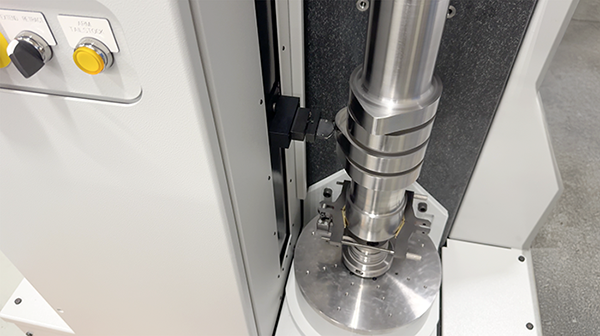

The system can measure over 20 parameters—including roundness, taper, lobe lift, and runout—ensuring comprehensive inspection capabilities. The Adcole 911 is capable of measuring shafts up to 104 inches (2,631mm) and up to 750 lbs (341 kg). For parts that exceed the width of the standard frame we offer a wide-body version for shafts with lengths up to 88.5 inches (2,248mm).

Beyond precision, the Adcole 911 gage is built for versatility and efficiency. It supports automated measurement routines, reducing labor costs and minimizing scrap through early defect detection. Optional features like the CamTracker for sidewall error measurement and the DiaMetric™ follower improves the submicron accuracy further, making it a valuable tool for manufacturers aiming to maintain tight tolerances and high product quality.

Specifications

| 911-24 | 911-36 | 911-36 WB | 911-60 | 911-60 WB | 911-90 | 911-90 WB | 911-105 | |

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolutioni | 0.016 µm | |||||||

| Angular Accuracy | <0.1 arc second (<0.0002º) | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| General Specifications | ||||||||

| Axis of Rotation | Vertical | |||||||

| Follower Stroke | 120mm (4.72”) | 120mm (4.72”) | 155mm (6.10”) | 120mm (4.72”) | 155mm (6.10”) | 120mm (4.72”) | 155mm (6.10”) | 120mm (4.72”) |

| Swing Diameter | 228mm (9”) | 228mm (9”) | 311mm (12.25”) | 228mm (9”) | 311mm (12.25”) | 228mm (9”) | 311mm (12.25”) | 228mm (9”) |

| Part Weight Max. | 341 kg (750 lb) | |||||||

| Part Length Max.ii | 583mm (23.0”) | 888mm (35.0”) | 993mm (39.1”) | 1,495mm (58.9”) | 1,473mm (58.0”) | 2,250mm (88.6”) | 2,248mm (88.5”) | 2,631mm (103.6”) |

| Base Gage Dimensions | ||||||||

| Gage Height | 2,004mm (80") | 2,229mm (90.5") | 2,426mm (95.5") | 2,908mm (114.5") | 3,556mm (140") | 3,937mm (155") | ||

| Gage Width | 887mm (34.9") | 1,087mm (42.8") | 938mm (36.94") | 1,087mm (42.8") | 1,146mm (45.1") | 1,280mm (50.4”) | 1,146mm (45.1") | |

| Gage Depth | 1,195mm (47") | 1,264mm (49.8") | 1,195mm (47") | 1,260mm (49.6") | 1,195mm (47") | 1,308mm (51.5") | 1,195mm (47") | |

| Gage Weightiii | 2,160 kg (4,760 lb) | 2,380 kg (5,250 lb) | 2,680 kg (5,900 lb) | 2,880 kg (6,350 lb) | 3,330 kg (7,340 lb) | 3,265 kg (7,200 lb) | 3,815 kg (8,410 lb) | 4,180 kg (9,220 lb) |

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.