Linear Profile Measurement Software

Overview

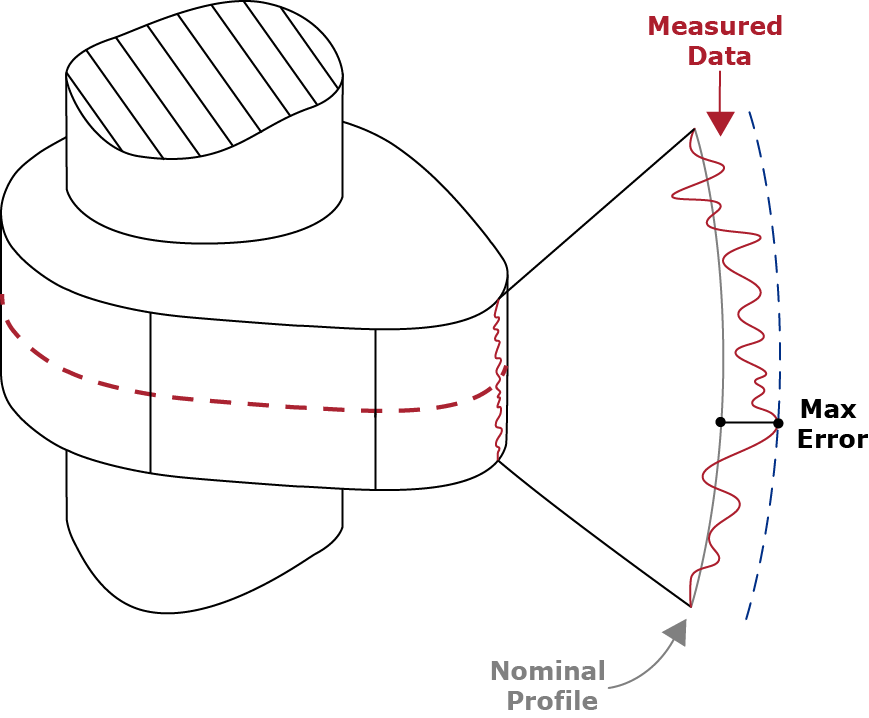

Adcole’s Linear Profile Measurement software provides a powerful solution for evaluating the geometry of journals and lobes by comparing a linear scan to a specified nominal radius. This radius is defined based on design specifications. The software calculates the largest positive error, the largest negative error, and the peak-to-valley error. It also enables users to visualize the measured profile alongside the nominal profile, complete with tolerance bands. Both the profile and the profile error can be displayed numerically and graphically, offering a comprehensive view of the part’s conformity to design.

Used in industries like automotive, aerospace, and industrial automation, the linear profile software ensures that parts such as camshafts, actuator rods, and transmission shafts are manufactured to precise specifications. It helps verify straightness, detect shape errors like barreling or misalignment, and confirm correct form and alignment, which are critical for performance, safety, and durability. By identifying deviations early, the software supports quality control, reduces rework, and ensures that components meet strict design and functional requirements.

Definitions

The software supports linear convexity, concavity, and barreling measurements, all presented in an intuitive and easy-to-understand format.

Linear Profile analysis is centered on mapping deviations from a known or specified profile radius. This functionality allows users to confirm that the grinding process is producing the correct form at the intended axial location. By plotting the profile and its associated errors, manufacturers can verify that their processes are accurate and within specification.

Linear Convexity is determined by identifying the maximum positive deviation of the scan data relative to a straight line drawn through the endpoints of the scan. If only a portion of the scan is being analyzed, the reference line is drawn through the endpoints of that specific segment.

Linear Concavity is calculated by finding the minimum deviation from the same type of reference line. This value may be positive or negative, depending on the shape of the profile. Like convexity, concavity is based on the relationship between the scan data and a straight line connecting the endpoints of the analyzed segment.

Linear Barreling focuses on the deviation of the center point of the scan relative to a straight line drawn through its endpoints. If the full scan is not used, the line is drawn through the endpoints of the selected data. The result can be either positive or negative. Unlike convexity, which considers the entire profile, barreling specifically evaluates the center point’s deviation, making it ideal for detecting barrel-shaped distortions.

Benefits

The software provides clear and easy-to-understand measurements for both linear convexity and concavity, along with detailed numeric and graphical profile data. It offers deep insights into the precision of complex, high-value components, helping engineers identify issues and improve manufacturing quality. With a complete set of analysis tools, it supports effective root cause analysis and process optimization.

Compatible Gages

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.