1200 Series Shaft Measuring Machines

Unrivaled Performance

Overview

When it comes to precision shaft metrology, the Adcole 1200 Series sets the industry standard. Designed for both production floors and metrology laboratories, the Adcole Models 1200-LX: High-Precision, 1200-HC: High-Capacity, and 1200-DH: Dual-Head deliver exceptional accuracy, reliability, repeatability, and value for advanced manufacturers.

What truly sets the 1200 Series apart from conventional tactile gages is its use of laser interferometry—a measurement technology that leverages light wave interference to detect minute displacements with extraordinary precision. This advanced method enables the 1200 Series to achieve radial measurement tolerances as tight as 0.25 µm, offering:

- Approximately 50% greater accuracy than single linear glass scale gages like the Adcole 911 and 1100-S

- Approximately 37% higher precision than dual glass scale systems such as the 1100-GX

With the Adcole 1200 Series, manufacturers gain a competitive edge in high-precision applications where every sub-micron counts.

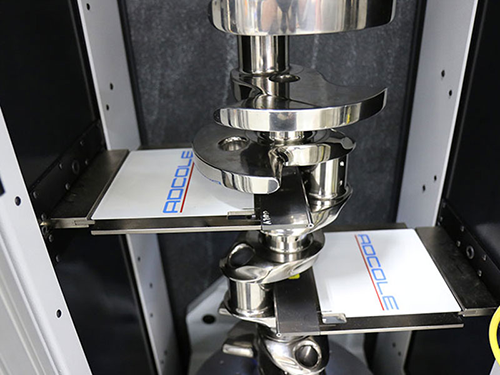

Laser Interferometery

Adcole 1200 gages utilize laser interferometry not to measure part surfaces directly, but to track the precise position of the machine’s moving components. The system incorporates four laser paths—one for axial positioning of the carriage and three for radial positioning of the tactile follower probe—ensuring exceptional accuracy and repeatability. Each interferometer splits a laser beam into two paths: one aimed at a fixed reference mirror and the other at a moving mirror attached to the carriage or probe. As the moving mirror shifts, the beams recombine to form an interference pattern, allowing the system to calculate displacement with sub-micron precision, often better than 0.05 µm.

The proprietary large mirrors featured in the 1200 family of gages are designed with a precision-ground reflective surface on a low thermal expansion substrate, maintaining accuracy even in extreme manufacturing environments. The laser interferometer and mirror architecture ensures that all measurements are based on real-time positional data, delivering best-in-class accuracy and traceability. Such precision is especially vital for high-performance components, where even the slightest deviation can impact functionality.

The 1200 Series is available in three models: the 1200-LX Ultimate Performance, 1200-HC High-Capacity, and 1200-DH Dual-Head & High-Throughput shaft gages

1200-LX: Ultimate-Performance Shaft Gage

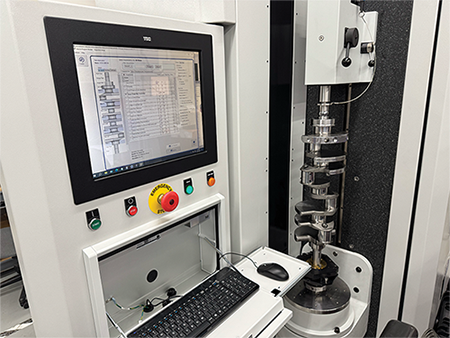

The Adcole 1200-LX is a high-performance shaft metrology gage designed to deliver exceptional precision in a compact, all-in-one unit. Engineered to conserve valuable production floor space, the 1200-LX integrates all measurement components, data processing, control systems, tooling and printer into a single streamlined unit, making it ideal for high-throughput manufacturing environments.

For facilities requiring a clean measurement environment, the 1200-LX offers an optional easy-swing door that encloses the measuring chamber that includes a Go/No-Go LED indicator to minimize contamination and provide immediate visual feedback on part conformity. This gage also features a swivel-hinge control panel that enhances operator ergonomics and accessibility.

Capable of handling parts weighing up to 240 kilograms (750 pounds), the 1200-LX is available in two configurations: a 1-meter model for shafts up to 1,000 millimeters (39.4 inches) in length, and a 1.5-meter model for shafts up to 1500 millimeters (59.1 inches). It supports a generous swing diameter of 300 millimeters (11.81 inches) and a follower slide stroke of 190 millimeters (7.5 inches), ensuring versatility across a wide range of shaft geometries.

Specifications

| 1200-LX (1M) | 1200-LX (1.5M) | |||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.25 µm | |||||||

| Radial Resolutioni | 0.005 µm | |||||||

| Axial Accuracy | ±1.0 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Rotation Speed | 1 to 20 RPM (Maximum 30 RPM) | |||||||

| Follower Stroke | 190mm (7.5") | |||||||

| Swing Diameter | 300mm (11.81") | |||||||

| Part Weight Max. | 340 kg (750 lb) | |||||||

| Part Length Max.ii | 1,000mm (39.4") | 1,500mm (59.1") | ||||||

| Carriage Speed | 2,286mm (90") per minute | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,535mm (99.8") | 3,043mm (119.8") | ||||||

| Gage Width | 1,396mm (55") | |||||||

| Gage Depth | 1,720mm (67.7") | |||||||

| Gage Weightiii | 3,986 kg (8,787 lb) | 4,700 kg (10,362 lb) | ||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons

1200-HC: High-Capacity Shaft Gage

For higher capacity requirements, the 1200-HC delivers exceptional accuracy and repeatability, powered by the same trusted laser interferometer technology as the 1200-LX but with a 52-86% larger swing diameter. With five models available to suit various shaft lengths and weights, the 1200-HC can accommodate shafts up to 4,572 mm (180 inches) in length and weighing up to 1,814 kg (4,000 lbs). Refer to the specifications for detailed model information.

Specifications

| 1200-HC (60") | 1200-HC (80") | 1200-HC (105") | 1200-HC (130") | 1200-HC (180") | ||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.4 µm | ±0.5 µm | ||||||

| Radial Resolutioni | 0.005 µm | |||||||

| Axial Accuracy | ±1.0 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.25 µm | |||||||

| General Specifications | ||||||||

| Rotation Speed Max. | 20 RPM | |||||||

| Follower Stroke | 270mm (10.63") | 330mm (13") | ||||||

| Swing Diameter | 457mm (18”) | 558mm (22") | ||||||

| Part Weight Max. | 1,360 kg (3,000 lb) | 1,814 kg (4,000 lb) | ||||||

| Part Length Max.ii | 1,524mm (60") | 2,062mm (81.2") | 2,671 mm (105.2") | 3,302mm (130") | 4,572mm (180") | |||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,692mm (106") | 3,163mm (124.5") | 3,772mm (148.5") | 4,426mm (174.3") | 5,715mm (225") | |||

| Gage Width | 2,446mm (96.3") | 2,756mm (108.5") | 2,954mm (116.3") | |||||

| Gage Depth | 1,529mm (60.2") | 1,621mm (63.8") | 1,946mm (76.6") | |||||

| Gage Weightiii | 3,630 kg (8,000 lb) | 5,900 kg (13,000 lb) | 7,044 kg (15,530 lb) | 11,110 kg (24,500 lb) | 19,050 kg (42,000 lb) | |||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

1200-DH: Dual-Head & High-Throughput Shaft Gage

As a part of Adcole’s flagship 1200 product lines, the 1200-DH is engineered for manufacturers who demand speed and accuracy, featuring dual laser interferometer systems for industry-leading measurement precision. The dual-head design dramatically reduces cycle times, helping you increase throughput without compromising quality.

With automation-ready capabilities, including robotic loading, the 1200-DH enables 100% in-line inspection, ensuring every part meets your standards—without slowing down your production line. Available in multiple sizes, it supports parts up to 1,520 mm (59.8 inches) in length and 1,360 kg (3,000 lbs) in weight, giving you the flexibility to handle a wide range of components with confidence.

Specifications

| 1200-DH (38") | 1200-DH (60") | |||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.25 µm | |||||||

| Radial Resolutioni | 0.005 µm | |||||||

| Axial Accuracy | ±1.0 µm / 100mm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Rotation Speed | 1 to 20 RPM (Maximum 30 RPM) | |||||||

| Follower Stroke | 190mm (7.5") | |||||||

| Swing Diameter | 302mm (11.88") | |||||||

| Part Weight Max. | 340 kg (750 lb) | |||||||

| Part Length Max.ii | 965mm (38") | 1,520mm (59.8") | ||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,348mm (92.4") | 2,889mm (113.8") | ||||||

| Gage Width | 2,682mm (105.6") | |||||||

| Gage Depth | 1,270mm (50") | |||||||

| Gage Weightiii | 4,310 kg (9,500 lb) | 5,896 kg (13,000 lb) | ||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.