Chatter Analysis Metrology Software

Overview

Chatter is a repeating pattern of small peaks or ‘undulations’ that occurs at regular intervals and can appear on the finished surface of a machined piece. As stated in the article, How to Determine if There is a Chatter Problem in a Grinding Process, in critical components, like a rotating shaft within an engine or motor, chatter can cause issues within the final assembly that could lead to premature part failure and damage other components.

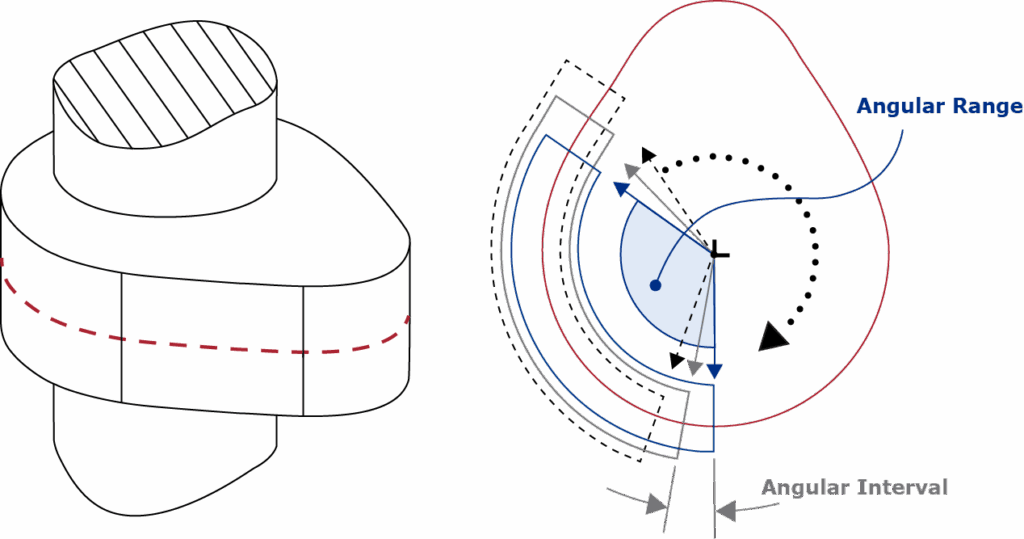

Adcole’s Real-Time Chatter Analysis (RTCA) software is engineered to detect localized chatter defects on shafts during the manufacturing process. Unlike traditional full-rotation analysis, RTCA uses a sliding window approach, scanning small angular segments (e.g., 10°–30°) to identify chatter that may only appear in specific regions. This makes it highly effective for spotting burst chatter, which can be missed in broader analyses. The software supports both box-region and formula-bounded tolerance limits and allows users to customize output thresholds and supports both individual and average lobe evaluations, making it a powerful tool for real-time quality control and grinder diagnostics.

The FFT Chatter Analysis software focuses on full 360° rotational analysis using Fast Fourier Transform (FFT) to convert surface profile data into the frequency domain. This method identifies consistent chatter patterns across the entire part, measuring Undulations Per Revolution (UPR) to detect and quantify vibration-induced surface defects. It’s particularly useful for diagnosing systemic issues in grinding machines and ensuring that parts meet stringent surface finish and dimensional standards. The software supports both square and custom tolerance curves, offering flexibility in quality assessment.

Together, these tools provide a comprehensive chatter detection solution: FFT Chatter Analysis excels at identifying persistent, machine-related chatter, while Real-Time Chatter Analysis is ideal for catching intermittent or localized defects. When used in tandem with Adcole’s high-precision gages, manufacturers gain a robust system for improving part quality, reducing scrap, and optimizing grinding processes.

Software Capabilities

Adcole’s chatter analysis software offers flexible integration, allowing it to be embedded directly into existing inspection sequences or used as a standalone post-process inspection tool. This adaptability makes it suitable for both inline and audit gage models. The software provides detailed insights by reporting the highest chatter amplitude and frequency (UPR) for each defined region, with results available in both tabular and graphical formats. Users can select amplitude output types based on their needs, including micrometers (μm) or decibels (dB), ensuring compatibility with various manufacturing standards.

Benefits

Adcole’s chatter analysis software supports a wide range of tolerance configurations, including single or multi-region box tolerances, as well as formula-based or file-based curved tolerances. It allows users to define specific angular ranges for inspection—such as full 360° analysis or targeted regions like base circles, ramps, and flanks—making it especially effective for detecting burst chatter on journals. The sliding window feature enables adjustments of the angular interval, enhancing the precision of localized chatter detection. Additionally, the software can analyze individual lobes or average lobe data, offering a comprehensive view of part quality.

By enabling manufacturers to detect chatter on shaft lobes, journals, and pin bearings, the software provides actionable data that supports process optimization and troubleshooting. This helps identify root causes of production issues, improve part quality, and enhance overall manufacturing efficiency. With multiple analysis methods and tolerance types, Adcole’s chatter software is a robust tool for improving profitability and maintaining high standards in precision machining.

Compatible Gages

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.