High-Precision Shaft Gages

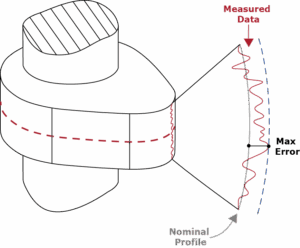

Adcole shaft metrology gages are built for high-precision measurement of critical shaft features that often far exceed the ten to one rule of resolution for required tolerances. Our gages can reach accuracies down to 0.2 microns (µm), depending on the gage type and configuration.

High-precision gaging is achieved through meticulous design and manufacturing of each component built into the gage. Decades of research and development on our spindle and bearing technologies provide the least amount of center positioning error. Our gages are built on granite for stability, vibration resistance, and low thermal expansion. Positional and angular accuracy are unmatched through the use of high-end linear and angular encoders as well as proprietary laser interferometer systems in Adcole 1200 series of gages.

Our high-precision gages support part lengths up to 4.5 meters, delivering fast cycle times and rapid part evaluation for demanding production environments. Designed for maximum throughput, our high-speed in-line gages can be equipped with up to 28 follower heads, ensuring comprehensive measurement with 3,600 data points per revolution.

Our High-Precision Shaft Gages

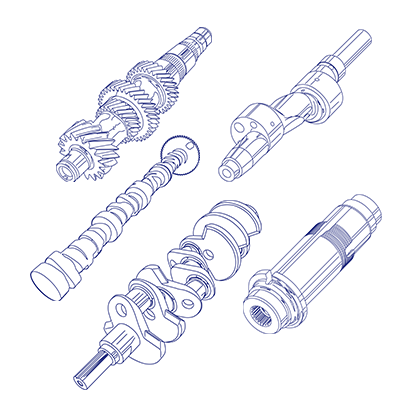

Adcoles offers a wide range of tactile gages that are well suited for many shaft types, features, and sizes. We start with one of our standard models and build around your unique parameters to provide you with a gage that improves your quality and value. Review our gage types below.

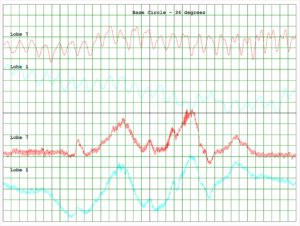

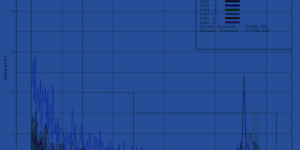

Every Adcole gage is powered by advanced software that delivers detailed numerical and graphical representations of complex metrology data—empowering your team to meet and exceed the highest quality standards. With increased demand for efficiency and performance in the next generation of motors and engines, precise measurements are of critical importance. Adcole gages are up to the challenge.

- Meet the most demanding GD&T measurement needs

- Provide automatic data collection and part traceability

- Are thoroughly developed and tested by Adcole Engineers

- Are robust and reliable backed by a comprehensive warranty

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your engineering review or service with one of our field service engineers.