1100 Series Shaft Measuring Machines

High Performance

Overview

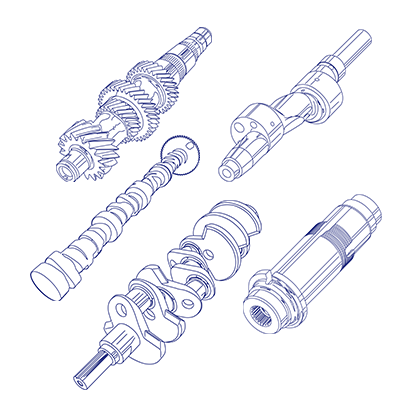

The Adcole 1100 series gages are high-precision cylindrical coordinate measuring machines (CCMMs) designed for inspecting critical rotating components like crankshafts, pistons, electric vehicle rotor shafts, and other cylindrical parts. The tried-and-true, high-performance, vertical audit shaft gages can measure many GD&T parameters with one-button testing to eliminate operator error and provide concise pass/fail inspection reports.

These gages are highly dependable and enable manufacturers to measure multiple part types and complex geometries using a flexible gage platform and our always exceptionally durable mechanical ball bearing spindle.

The 1100 Series shaft metrology gages come in two models, the 1100-S and the 1100-GX.

1100-S: High-Performance Shaft Gage

Built to the same exacting standards that define every Adcole “Trusted Accuracy” gage, the 1100-S is designed to help manufacturers improve part quality, reduce scrap, and boost production efficiency. This model builds on the proven capabilities of the 911 series, with a redesigned physical structure that accommodates wider components—such as crankshafts—by extending the follower slide stroke to a maximum of 198 mm (7.8 inches) and increasing the swing diameter to 316 mm (12.4 inches).

The 1100-S is available in two sizes:

- 1 meter, supporting part lengths up to 993 mm (39.1 inches)

- 1.5 meter, supporting part lengths up to 1,473 mm (58 inches)

Specifications

| 1100-S (1M) | 1100-S (1.5M) | |||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.5 µm | |||||||

| Radial Resolutioni | 0.1 µm | |||||||

| Axial Accuracy | ±2.0 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.15 µm | |||||||

| General Specifications | ||||||||

| Axis of Rotation | Vertical | |||||||

| Follower Stroke | 198mm (7.8") | |||||||

| Swing Diameter | 316mm (12.4") | |||||||

| Part Weight Max. | 225 kg (500 lb) | |||||||

| Part Length Max.ii | 993mm (39.1") | 1,473mm (58") | ||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,426mm (95.5") | 2,908mm (114.5") | ||||||

| Gage Width | 1,087mm (42.8") | |||||||

| Gage Depth | 1,264mm (49.8") | |||||||

| Gage Weightiii | 2,676 kg (5,900 lb) | 3,330 kg (7,340 lb) | ||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

1100-GX: Superior Performance Shaft Gage

If your application demands tighter radial tolerances and enhanced functionality, the 1100-GX is the next evolution in our gage lineup. Engineered for high-precision measurement, the 1100-GX achieves radial accuracy down to 0.40 µm, thanks to its dual glass-scale linear encoders. It can measure a typical crankshaft in an average of just 4 minutes, delivering both speed and precision.

All components of the 1100-GX are integrated into a single compact unit, eliminating the need for an external computer cabinet and conserving valuable production floor space. For added convenience and quality control, the gage also offers an optional part enclosure door equipped with Go/No-Go LED indicators to provide immediate pass/fail feedback.

The 1100-GX is available in two sizes:

- 1 meter, supporting part lengths up to 1,067 mm (42 inches)

- 1.5 meter, supporting part lengths up to 1,575 mm (62 inches)

Specifications

| 1100-GX (1M) | 1100-GX (1.5M) | |||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Radial Accuracyi | ±0.4 µm | |||||||

| Radial Resolutioni | 0.016 µm | |||||||

| Axial Accuracy | ±2.0 µm | |||||||

| Angular Resolution | <0.036 arc second (<0.00001°) | |||||||

| Total Spindle Runout | <0.1 µm | |||||||

| General Specifications | ||||||||

| Axis of Rotation | Vertical | |||||||

| Follower Stroke | 190mm (7.5") | |||||||

| Swing Diameter | 300mm (11.81”) | |||||||

| Part Weight Max. | 340 kg (750 lb) | |||||||

| Part Length Max.ii | 1,067mm (42") | 1,575mm (62") | ||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 2,535mm (9.8") | 3,043mm (119.8") | ||||||

| Gage Width | 1,396mm (55") | |||||||

| Gage Depth | 1,720mm (67.7") | |||||||

| Gage Weightiii | 3,890 kg (8,575 lb) | 4,488 kg (9,895 lb) | ||||||

i Temperature 20±1 C°, Relative Humidity 40%-60%, Pressure 86KPa-106KPa.

ii Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

iii Weight does not include add-ons or cabinet

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your service with one of our field service engineers.