In-Line Shaft Gages

For Production Environments

Adcole gages can be seamlessly integrated into both new and existing production lines to enable fully automated shaft measurement solutions. Our gages are designed and built for the high-capacity and high-throughput demands of modern manufacturing operations. Process control can be taken a step further by implementing feedback to grinding operations to maintain production quality and help quarantine out-of-spec parts to ensure consistent quality standards. Our in-line models can also work with automated robot or gantry arm part loaders for smooth, hands-free operations.

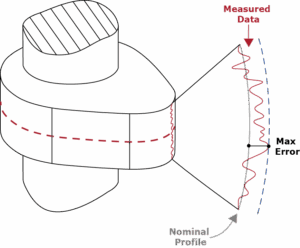

The in-line shaft gages are the best-in-class measurement tool for a diverse range of shaft types. Measure flatness, taper, center deviation, roundness, throw and more using Adcole’s range of easy-to-use and powerful software that brings valuable data into your operations.

Our In-Line Shaft Gages

- Come in vertical and horizontal configurations

- Can be integrated into existing production lines and communicate with other equipment

- Can be outfitted with multiple measuring heads for fast cycle time

- Can communicate with robotic systems for automatic part load /unload

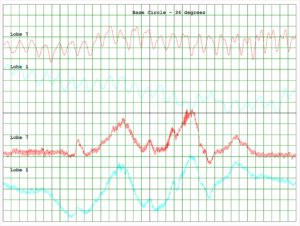

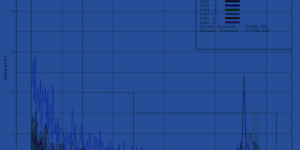

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your engineering review or service with one of our field service engineers.