Surface Roughness Measurement

Gages for Surface Finish

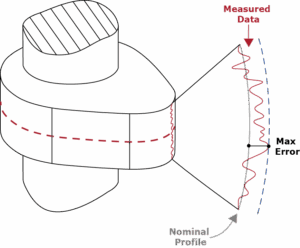

Surface finish or texture of shaft features that have tight fits or move against each other are commonly overlooked when considering the end quality and the overall impact it can have on performance. Surface finish refers to the inherent irregularities left by the manufacturing process—such as grinding, turning, or honing.

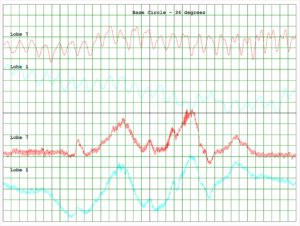

To accurately assess surface finish, it’s essential to evaluate three key characteristics: lay, waviness, and roughness — particularly on critical shaft features such as journals and thrust surfaces. These parameters collectively define the texture of a machined surface and are crucial for ensuring proper function and longevity of rotating components.

It’s important to distinguish surface finish from chatter, which is a distinct phenomenon. Chatter manifests as a repeating pattern of small, evenly spaced peaks or undulations caused by vibrations during machining. While chatter can appear on a finished surface, it is not a component of surface finish measurement.

Types of Surface Roughness Shaft Gages

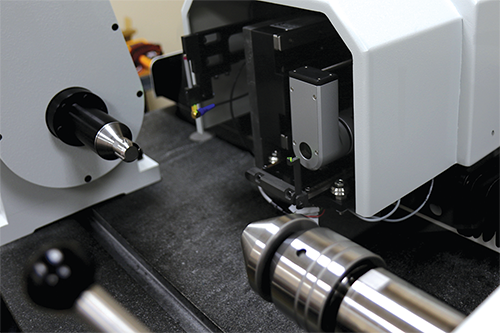

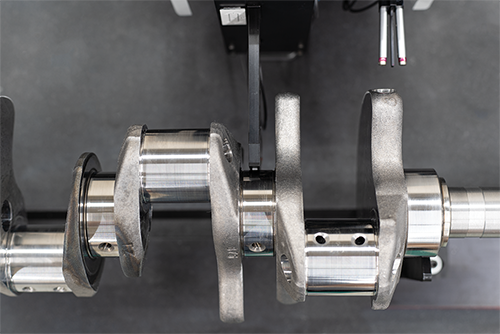

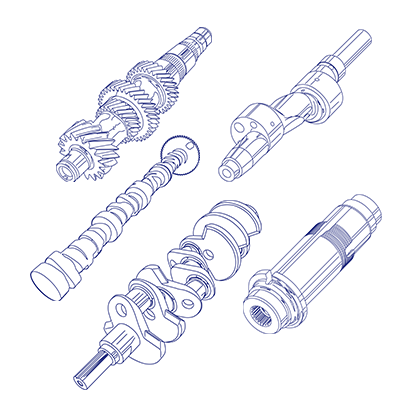

Adcole surface roughness measurement gages are purpose-built for inspecting camshafts and crankshafts, gears and transmission shafts, and other finely machined cylindrical components. Engineered for horizontal loading, it delivers rapid surface measurement cycles and industry-leading accuracy in part inspection data and features a granite surface plate with integrated headstock, tailstock, and carriage—ensuring mechanical stability and repeatable performance in demanding environments.

- Gage uses commonly available stylus tip sizes: 2 µm, 5 µm, or 10 µm radius diamond tipped, ruby skidded probes, or through skid probe types in 2 µm and 5 tip µm radii

- Automated, push-of-a-button gage provides high density part data – 2000 data points per mm

- Fast cycle times for improved throughput

- Easy-to-use operator interface

Adcole Surface Roughness Gages can be broken down into three types; fully-tactile, optical and tactile combination, or fully-optical.

1000: Automated Surface Roughness Shaft Gage

Leveraging tactile, stylus-based metrology, the Model 1000 Automated Surface Roughness Shaft Gage offers a comprehensive and reliable solution for quality assurance with a vertical resolution of less than 1 nm and a lateral resolution of 0.5 µm. The max part length is 36 inches (915mm) and weight is 222 pounds (100 kg) with a swing diameter of 6.7 inches (170mm).

Specifications

| 1000 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Vertical Resolution | <1 nm | |||||||

| Range | 40 µm | |||||||

| Lateral Resolution | 0.5 µm | |||||||

| Overall Error | <10% of typical industry part tolerance | |||||||

| General Specifications | ||||||||

| Axis of Rotation | Horizontal | |||||||

| Swing Diameter | 170mm (6.7") | |||||||

| Part Weight Max. | 100 kg (222 lb) | |||||||

| Part Length Max.i | 915mm (36") | |||||||

| Rotation Speed | 1 - 20 RPM | |||||||

| Measuring Speed | 1mm/s (adjustable) | |||||||

| Technical Specifications | ||||||||

| Tip Radius | 2, 5 or 10 micrometers | |||||||

| Style Force | 0.7mN to 1 mN selectable | |||||||

| Stylus Lift-off | Automatic / Programmable | |||||||

| Cut-off Value | 0.08 to 8.0 mm (0.003” to 0.3”) configurable | |||||||

| Evaluation Length | 4 mm (adjustable) | |||||||

| Filter | 2CR, Gaussian, Robust Gaussian | |||||||

| Probe Types | 2 μm, 5 μm, 10 μm radius diamond tipped, ruby skidded inductive probes. 2 μm, 5 μm radius through skid probe types | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 1,575mm (62") | |||||||

| Gage Width | 762mm (30") | |||||||

| Gage Depth | 1,321mm (52") | |||||||

| Gage Weight | 2,495 kg (5,500 lb) | |||||||

i Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

Capacities

| 1000 | |||||||

|---|---|---|---|---|---|---|---|

| Features Measured | |||||||

| Main bearing journals | |||||||

| Pin journal sidewalls | |||||||

| Post and flange diameters | |||||||

| Rod journals | |||||||

| Thrust faces | |||||||

| Camshaft journals and lobes | |||||||

| Roughness Parameters - Tactile | |||||||

| Ra | Rp | Tp (Rmr) | Rsk | ||||

| Htp-1/2/3/4/5/6 (Rdc) | Rt | Rpm | RzDIN | ||||

| Rp/Rt | Rk | Rpk | Rvk | ||||

| MR1 | MR2 | R3z | RzJIS | ||||

1000-Z: Tactile & Optical Surface Roughness Shaft Gage

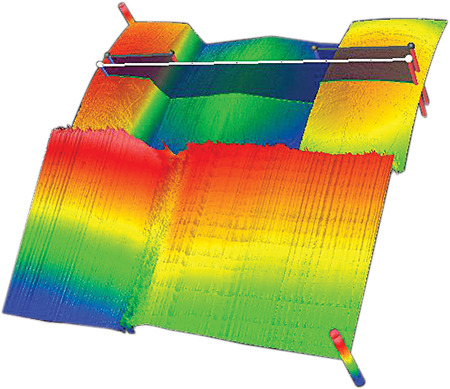

The Adcole Model 1000-Z features both optical and tactile measuring heads to deliver high-precision surface measurements. The non-contact, ZYGO© white light, interferometric probe expands on the measurement capabilities from the diamond-tipped contact probe of the standard Adcole 1000 gage. The optical accessory can precisely measure surface finish of hard-to-reach features such as groove bottoms, sidewalls, and more with a resolution of less than 1 nm.

By adding the optical accessory, the measurement area expands from a single contact probe line to a 3D surface area measuring 3.3 x 3.3 mm. This significantly increases the number of data points collected, enabling a flexible and more comprehensive surface analysis with improved insight into part quality.

The 1000-Z gage quantifies surface roughness to ensure manufacturing quality and detect potential issues. These measurements are vital in tribology, where surface texture—such as roughness, waviness, and form—directly affects friction, wear, and lubrication. Even minute topographical variations can influence how components interact under load.

1000-ZS: Optical Surface Roughness Shaft Gage

For cost considerations, the 1000-Zs is built absent of all tactile features to be a fully ZYGO optical surface roughness gage.

Specifications

| 1000-Z | ||||||||

|---|---|---|---|---|---|---|---|---|

| Accuracy Specifications | ||||||||

| Vertical Resolution | <1 nm | |||||||

| Range | 40 µm | |||||||

| Lateral Resolution | 0.5 µm | |||||||

| Overall Error | <10% of typical industry part tolerance | |||||||

| General Specifications | ||||||||

| Axis of Rotation | Horizontal | |||||||

| Swing Diameter | 170mm (6.7") | |||||||

| Part Weight Max. | 100 kg (222 lb) | |||||||

| Part Length Max.i | 915mm (36") | |||||||

| Rotation Speed | 1 - 20 RPM | |||||||

| Measuring Speed | 1mm/s (adjustable) | |||||||

| Technical Specifications | ||||||||

| Lateral Resolution - Tactile | 0.5 µm | |||||||

| Lateral Resolution - Optical | 3.3 µm | |||||||

| Evaluation Length - Tactile | 4mm (adjustable) | |||||||

| Evaluation Length - Optical | 3.3mm x 3.3mm | |||||||

| Resolution | <1 nm | |||||||

| Stylus Force | 0.7mN to 1 mN selectable | |||||||

| Stylus Range | 40 µm | |||||||

| Cut-off Value | 0.08 to 8.0 mm (0.003” to 0.3”) configurable | |||||||

| Filter | 2CR, Gaussian, Robust Gaussian | |||||||

| Base Gage Dimensions | ||||||||

| Gage Height | 1,575mm (62") | |||||||

| Gage Width | 762mm (30") | |||||||

| Gage Depth | 1,321mm (52") | |||||||

| Gage Weight | 2,495 kg (5,500 lb) | |||||||

| Sensor Specifications | ||||||||

| Tactile | Diamond tipped skidded inductive | |||||||

| Optical | Non-contact 3D Coherence Scanning Interferometry (CSI) | |||||||

i Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

Capacities

| 1000 | |||||||

|---|---|---|---|---|---|---|---|

| Features Measured | |||||||

| Main bearing journals | |||||||

| Pin journal sidewalls | |||||||

| Post and flange diameters | |||||||

| Rod journals | |||||||

| Thrust faces | |||||||

| Camshaft journals and lobes | |||||||

| Roughness Parameters - Tactile | |||||||

| Ra | Rp | Tp (Rmr) | Rsk | ||||

| Htp-1/2/3/4/5/6 (Rdc) | Rt | Rpm | RzDIN | ||||

| Rp/Rt | Rk | Rpk | Rvk | ||||

| MR1 | MR2 | R3z | RzJIS | ||||

| Roughness Parameters - Optical | |||||||

| Ra | Rsk | Rpm | RzDIN | ||||

| R3z | Rmax | ||||||

i Max. part length is approximate. Actual length is dependent on center tooling style, part center hole configuration, amount of TS travel needed to clear customer part, etc.

Software

These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Applications

Measuring quality is essential for ensuring that products meet specified standards and perform reliably. These tools often include features for tracking defects, analyzing performance metrics, and generating detailed reports. By providing insights into areas for improvement, Adcole gage software helps your organization maintain the highest standards and continuously enhance your products.

Comprehensive Engineering & Technical Support

Our team of dedicated engineers is ready to help you with any needs regarding your Adcole shaft metrology gage. We offer global technical support, training, upgrades for your gage, and gage recertification. Contact us today to schedule your engineering review or service with one of our field service engineers.